Discover Our Extensive Product Range

With our wide range of filter systems, we offer you a customizable solution for your filtration requirements. From fine filtration of oils to cleaning of coolant lubricants, we provide a variety of machines to meet your needs. Our filter systems are characterized by high performance, easy operation and maintenance, as well as long service life.

Plate Precoat Filter

Chain Magnetic Separator

Pressure Belt Filter

Vacuum Filter

Hinged Belt Filter

Automatic Precoat Filter

Automatic Hinged Belt Filter

Multifunctional Filter

Machines for Optimal Filtration Results

At F.E.S., you will find not only standardized machines but also custom solutions tailored to your specific needs. We can customize parts of your machines or develop new filter systems.

Plate Precoat Filter

Advantages: Efficient filtration with precoat layer, easy cake discharge, high solids retention capacity

Industries: Chemical, Pharmaceutical, Food and Beverage

Plate precoat filters are used for fine filtration applications where a precoat layer is formed on the filter medium. The precoat layer enhances the filtration efficiency and allows for easy cake discharge. These filters are commonly used in the chemical, pharmaceutical, and food and beverage industries.

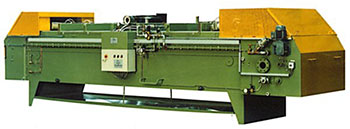

Chain Magnetic Separator

Advantages: Effective removal of magnetic contaminants, high flow capacity, low maintenance

Industries: Mining, Recycling, Materials Handling

Chain magnetic separators are designed to remove magnetic particles and contaminants from bulk materials. The magnetic chain moves the particles along the separator, allowing for efficient separation. These separators are commonly used in mining, recycling, and materials handling industries.

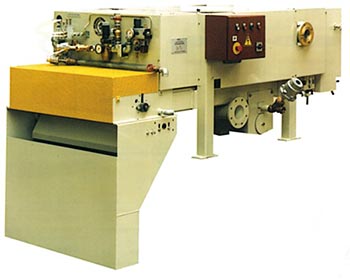

Pressure Belt Filter

Advantages: High throughput capacity, no backwashing during regeneration, easy discharge of filter cake.

Industries: Primarily used in metal processing and rolling mill industries.

The belt filter is used in metal processing and rolling mill applications for the cleaning of contaminated cutting fluids. The cleaned cutting fluids have an extended service life and improve the surface quality of workpieces or rolled goods. Additionally, the filter facilitates heat dissipation at the processing or forming location.

Vacuum Filter

Advantages: Continuous operation, high filtration efficiency, easy maintenance

Industries: Mining, Chemical, Environmental

Vacuum filters utilize suction to extract liquid through a filter medium, resulting in efficient solid-liquid separation. These filters are suitable for a wide range of applications in industries such as mining, chemical, and environmental.

Hinged Belt Filter

Advantages: Continuous operation, high filtration efficiency, easy cake discharge

Industries: Metalworking, Automotive, Machining

The belt filter press is used in metal processing and rolling mill operations for cleaning contaminated coolant lubricants. The cleaned coolant lubricants have a longer service life and improve the surface quality of workpieces or rolled goods. Additionally, the filter aids in heat dissipation at the processing or forming site.

Automatic Precoat Filter

Advantages: Fully automated operation, efficient cake formation, extended filter media lifespan

Industries: Chemical, Pharmaceutical, Food and Beverage

Automatic precoat filters employ a precoat layer on the filter medium to enhance filtration efficiency. These filters offer fully automated operation, ensuring efficient cake formation and prolonged filter media lifespan. They are commonly used in the chemical, pharmaceutical, and food and beverage industries.

Automatic Hinged Belt Filter

Advantages: Fully automated operation, high throughput, low maintenance

Industries: Metalworking, Automotive, Machining

Automatic hinged belt filters provide fully automated filtration for coolant lubricants in metalworking applications. These filters offer high throughput, minimal operator intervention, and low maintenance requirements, enhancing overall process efficiency.

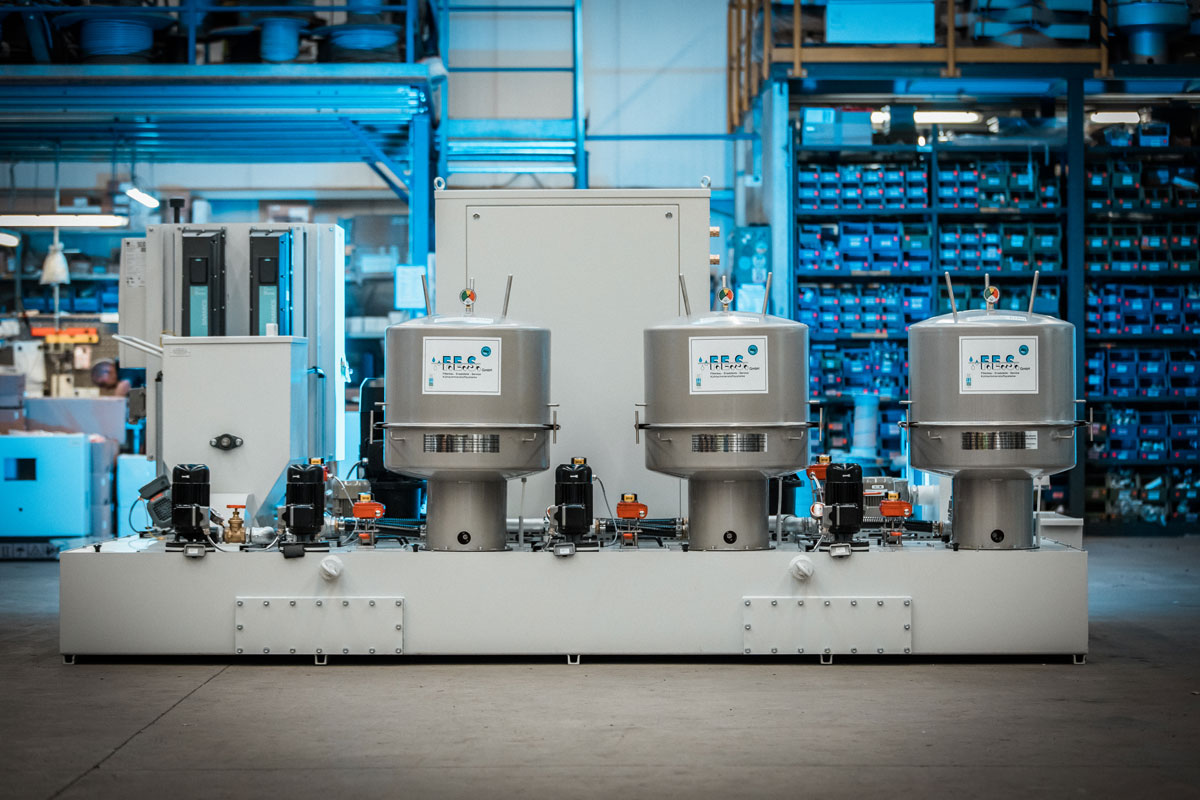

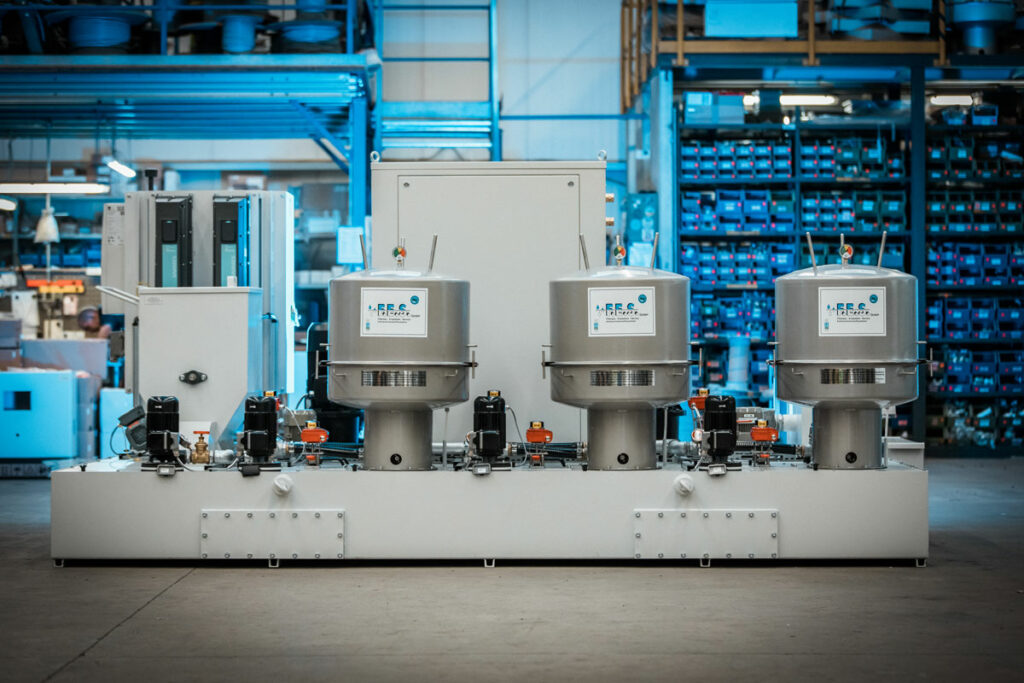

Multifunctional Filter

Advantages: Low backwash losses and minimal misting during backwashing. PLC technology.

Industries: Metal processing, food, chemical, and petrochemical industries.

Multifunctional filters are used for fine filtration of low-viscosity oils with low levels of contamination. These filter systems are multifunctional and can be operated as flush filters or edge filters as desired. Conversion can be done easily and without much effort. Due to their adaptability to various filtration tasks, these systems are highly suitable.

SULPHEX I

Advantages: Reduction of sulfur content in the coolant, purely physical process without chemical impact.

Industries: Metal processing, automotive industry, and mechanical engineering.

The SULPHEX I sulfur separator by F.E.S. is suitable for all industries where dissolved sulfur is a problem. This patented process works purely physically and has no chemical impact on the machining oil used. The separator is used in bypass operation to reduce the sulfur content in the main circuit and stabilize it at an acceptable level.